5 Tips to Keep Heavy Equipment Operators Safe

The Life of a Heavy Equipment Operator is Dangerous

Danger is all around us—from cracks in the sidewalk to careless drivers on their phones—but when you make your living as a heavy equipment operator the risk of injuring yourself or others is imminent. One wrong move, one forgetful moment, one lapse in judgment could send tons of machinery and materials tumbling to the ground below and onto whatever (or whoever) is in the way.

That’s why effective safety training at heavy-machine operator schools is so important. It’s not enough that these individuals know and understand proper, safe procedures for using their equipment responsibly, those best practices and safe habits must be ingrained, automatic, and a part of their everyday routine.

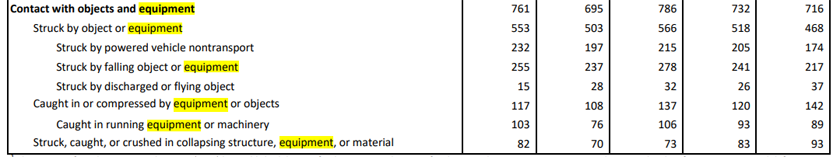

The Bureau of Labor Statistics (BLS) reported nearly 800 accidents involving machinery on job sites all around America in 2021.

But it’s not enough for a crane operator to know hand signals and how to read a load chart. A heavy equipment operator must know all aspects of safe operation from calculating capacities to site preparation to safe movement and beyond. They even need to know how to separate themselves from common habits they may have adopted behind the wheel of their personal automobile. (Distraction is one of the leading causes of heavy equipment accidents in the United States.)

That’s why the best schools for heavy equipment operators give these individuals all the skills they need to succeed in their job and do it safely—not just cover the bare minimums to pass their certification exams. Nationwide Crane Training offers a variety of heavy equipment classes that motivated individuals can use in multiple industries. Our dedicated curriculum and expert instructors can teach everything from general job site safety—including OSHA qualification—to specific NCCCO crane operator certification on multiple types of machinery.

Here, a few specific safety tips that crane operators can use to work safely, remain productive, and stay alert behind the controls.

5 Tips to Keep Mobile Crane Operators Safe

1. Injury can happen before the machine is even on

Entering and exiting the machine’s control cockpit are two of the most dangerous times for heavy equipment operators. Having to hoist yourself up steps or climb ladders while wearing bulky safety equipment can be dangerous. Falls are commonplace and they can result in more than just a bump on the noggin or a bruised backside. In fact, according to the BLS, there were almost 40 fatal accidents in the United States in 2021 involving individuals falling from machinery. So remember:

- Always maintain three points of contact

- Make sure your boot treads are clear of slippery debris, like mud

- Ensure your gloves are in good shape without any holes or tears

2. Distraction is a killer

The BLS reports that distraction is one of the most common causes of fatal or injurious accidents involving heavy machinery. When you think about it, it makes sense, as distraction is also one of the most common causes of fatal or injurious automobile accidents in the U.S.

Keep your cockpit clear of distractions. Leave the cell phone in your car or locker. Don’t take anything that’s unnecessary—including food and beverages—with you in the operator’s seat. Ensure you get plenty of sleep the night before, so your mind is clear and you can focus.

3. Commonly overlooked safety procedures result in avoidable accidents

Inexperience can lead operators to forget necessary safety precautions, but experience can breed complacency, and old-timers may think they can overlook certain precautions without risk. However, something as mindless as forgetting to engage a parking brake or not completely lowering blades or attachments, or even failing to run equipment at low idle for long enough before flipping the “off” switch can create havoc. That’s why it’s a good idea to create a mental checklist of all the safety protocols and always follow every step—even if you don’t think it’s absolutely necessary.

4. Seatbelts save lives

Seatbelts aren’t just for your ride home. Safety harnesses inside heavy equipment are there to prevent operators from tumbling out of the cockpit and possibly getting trapped or crushed under equipment if it tilts, falls, or rolls over. Click it every time.

5. A clear AO is essential

You don’t want to be the cause of someone else’s tragedy. That’s why situational awareness is one of the most essential safety skills heavy equipment operators can learn. Always know where everyone and everything is within your AO (area of operations) at all times to avoid collisions.

The Best School for Heavy Equipment Operators

Want to learn more about how to avoid accidents and injuries at the job site? Nationwide Crane Training offers a variety of safety classes ranging in complexity from general laborer safety and minimum OSHA qualification to equipment-specific crane operator training and certification. Contact us to learn more about the classes we offer, where you can enroll, or how your business can schedule a private class at a location of your choosing.